Know how to achieve operational excellence

Silos, scattered internal systems, and lack of clear communication often result in disconnected, futile efforts to leverage know-how.

qibri gives content ownership to experts and empowers them to provide their know-how with ease. It is the simple way to develop, keep and drive excellence.

Unmet operational excellence goals

Every day, operations leaders work to eliminate errors, deliver high-quality products and services on time, ensure employee safety, and onboard teams efficiently. All this, while striving to build consistent processes and foster a culture of continuous improvement. Despite these efforts, the reality often doesn’t live up to the ambition.

What’s blocking your team’s excellence?

qibri to improve

Lacking Productivity

Unclear guidance and individual approaches, hindering standardization and harmonization opportunities.

qibri to anchor

Stalled Transformation

Teams unaware of how transformation efforts impact daily work, leading to increased resistance.

qibri to enhance

GenAI reliability

Unstructured and outdated content fed into LLMs (Chat-GPT-like models), leading to unrealiable answers.

Why do most efforts fail?

Too many companies treat know-how management as an one-off and isolated effort, missing the critical link between know-how and daily operations.

Content cleanup is done once and forgetten. Soon teams find themselves back where they started.

Chaos reigns. Everything gets put into one pile without structure and clear ownership.

Existing silos are carried into know-how database blocking harmonization opportunities.

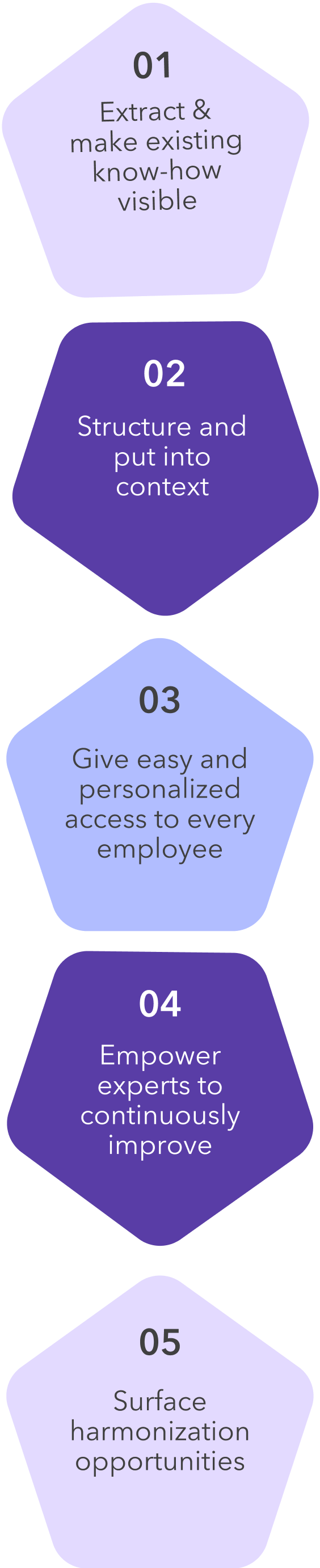

qibri, easiest way to weave know-how into operations

Our platform ensures teams do not revert to old habits and provides reliable, trusted information to everyone across the organization. Hence, it democratizes know-how across the organization, paving the road to operational excellence.

We aim to create a big impact

reduction of redundant know-how content

Basierend auf Studien mit über 300

Unternehmen beträgt die

durchschnittliche Suchzeit für eine

Guideline 30 Minuten. qibri

ermöglicht es jedem Mitarbeiter und

jeder Mitarbeiterin, jede Guideline in

weniger als 3 Minuten zu finden.

know-how documents processed so far

Case Study: Brantner green solutions

A prominent player in waste management with 65 branches and joint ventures in five countries, Brantner green solutions faced a major challenge on its path to operational excellence: Diverse approaches of different units and branches led to organizational clutter, hindering productivity and slowing down transformation efforts.

Learn how qibri reduced 40% of organizational clutter and achieved visibility and continuous improvement across 15 organizational units.

What our clients have to say

C-level executives, SVPs, function heads, and transformation managers create impact with qibri

The structured management of guidelines turned out to be an important driver for the sustainable success of our productivity initiatives – for many unexpectedly.

Dr. Alois Virag

CEO Puraglobe

former Chief Transformation Officer, OMV & CEO of Naraya Energy

The essential thing is that we do it [know-how management] in a way that it supports, helps, both the business, and especially, the employees.

Tim Holzapfel

SVP Transformation, Siemens AG

It is exciting to see that qibri turned out to be a driver of corporate culture transformation. I didn’t expect that. Since its implementation, it actually led the democratization of decision-making processes.

Josef Scheidl

Managing Director, Brantner green solutions